|

Robotic Ropes - Metal Micro Ropes

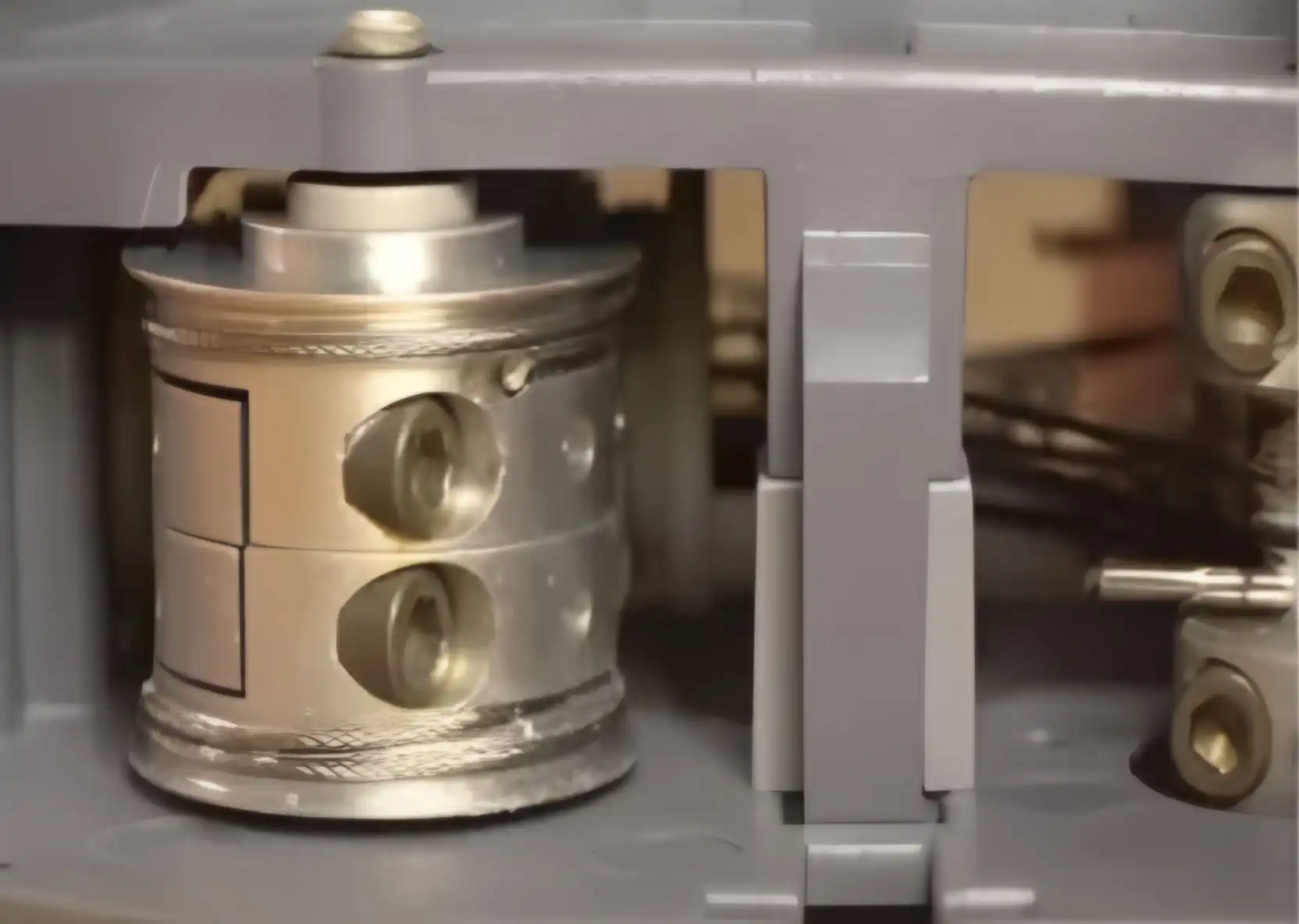

I. Structure:

Figure 1: Structure

II. Application:

Applications in power transmission, tendon drive, sensors, and other transmission

and auxiliary mechanisms within industrial robots, dexterous hands, micro grippers,

space robots, nuclear industry robots, deep-sea robots, etc.

1. Advantages:

- Full specification coverage for diverse applications;

- Customizable freedom: Any combination of wire gauge, length, and terminals;

- High strength and fatigue resistance for lasting reliability;

- Low creep and small bending radius for effortless adaptation to complex curves;

- Exceptional flexibility for smoother motion.

2. Performance Parameters:

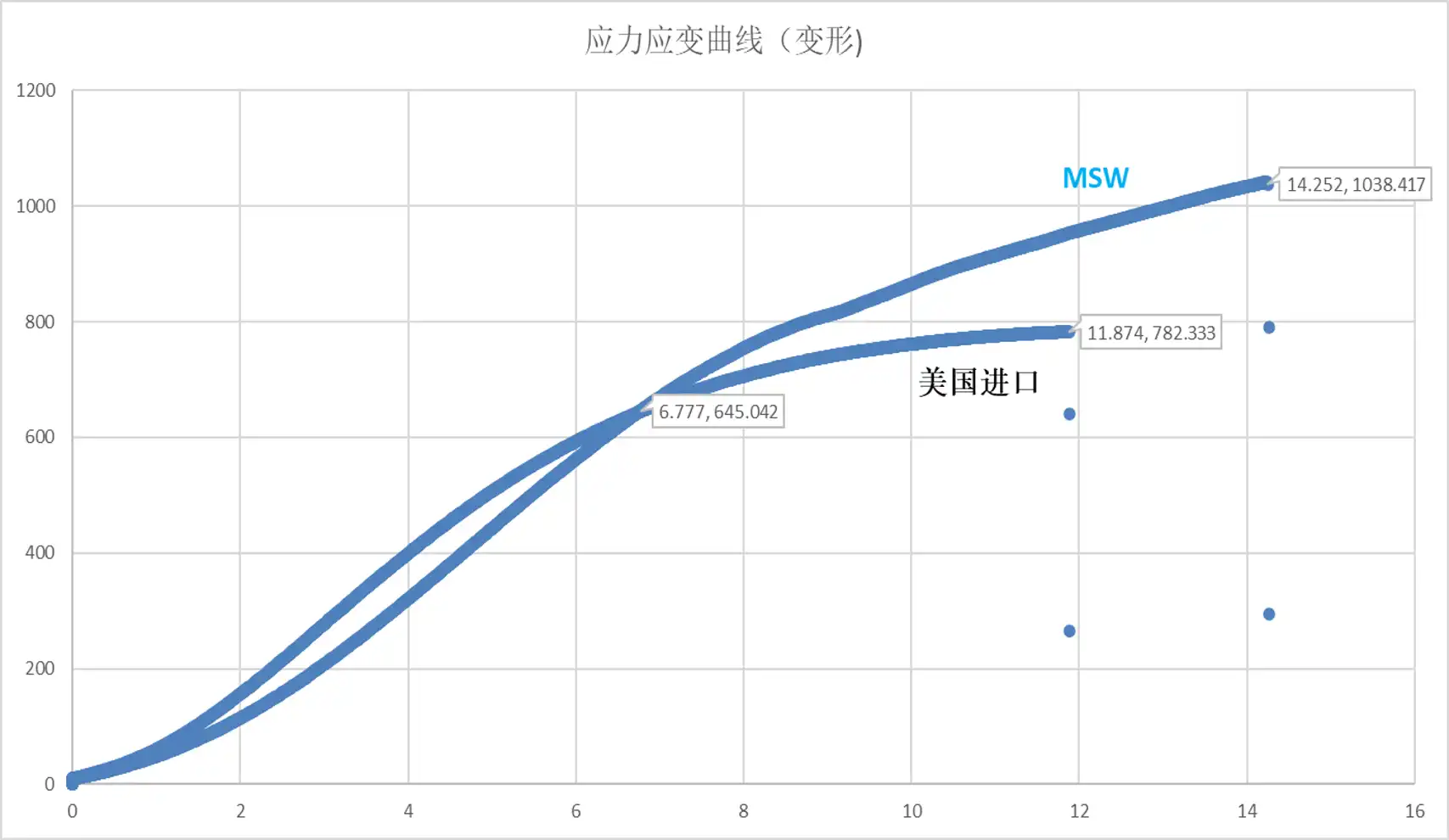

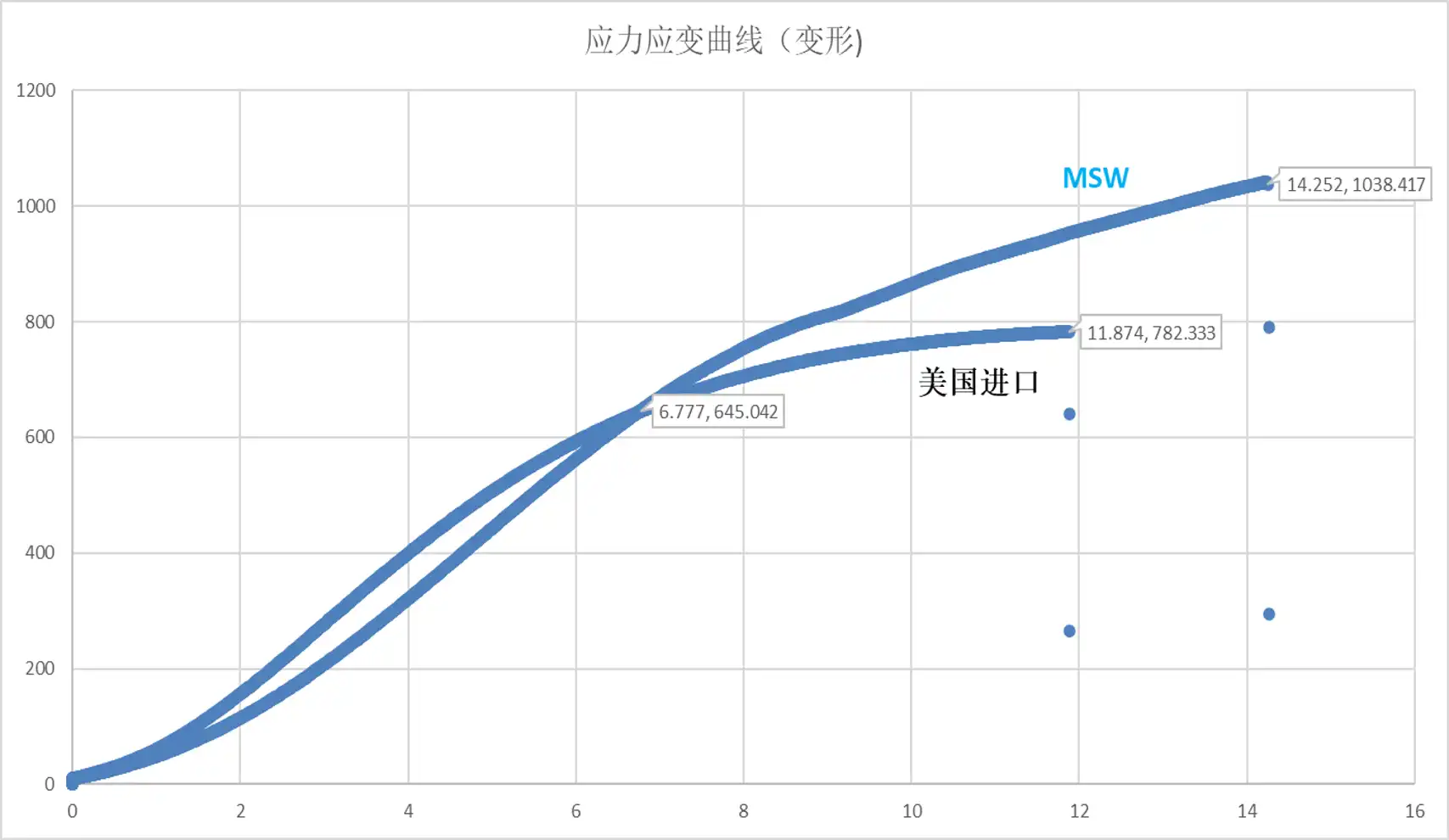

Benchmark Comparison:

Figure 2: Performance Comparison

Parameter Table:

|

Parameter Table

|

| Material |

Diameter (mm) |

Structure |

Breaking Strength (N) |

| Tungsten Wire Rope |

0.50 |

7*7+8*19 |

≥380 |

| Tungsten Wire Rope |

0.76 |

7*7+8*19 |

≥1000 |

| Tungsten Wire Rope |

0.76 |

19*19 |

≥1000 |

| Tungsten Wire Rope |

1.00 |

7*7+8*19 |

≥1200 |

| Tungsten Wire Rope |

1.50 |

7*49 |

≥2500 |

| Tungsten Wire Rope |

2.80 |

7*49 |

≥4500 |

| Stainless Steel |

3.00 |

7*49 |

≥4500 |

| Stainless Steel |

4.00 |

7*49 |

≥6000 |

Table 1: Parameter Table

- Tungsten wire ropes are available with surface treatment solutions to improve friction conditions during operation;

- Surface treatment solutions are customized according to customer requirements;

|